Do you have a concept or an idea or for a new product?

Maybe you also have designs ready and are now wondering how to get it manufactured.

Or even how to begin selecting a manufacturing partner.

This article will help you understand the differences between two common outsourced manufacturing business models – ODM and OEM – and show you how you could select one or the other.

Topics

Here’s what we’ll cover in this article.

- What is ODM

- What is OEM

- Examples of ODMs and OEMs

- Pros and Cons of ODMs and OEMs

- How to choose between an ODM or an OEM

- Key Takeaways

OEMs and ODMs: Definitions

OEM stands for Original Equipment Manufacturer.

An OEM manufactures a product designed by someone else.

ODM stands for Original Design Manufacturer.

An ODM manufactures a product designed by itself.

Yes, these are broad definitions and in practice, you may come across an OEM that offers design services or design advice and an ODM which can manufacture a product based on someone else design inputs.

But these broad definitions are a good start to understand the differences in the business models of ODMs and OEMs and eventually picking one model over the other.

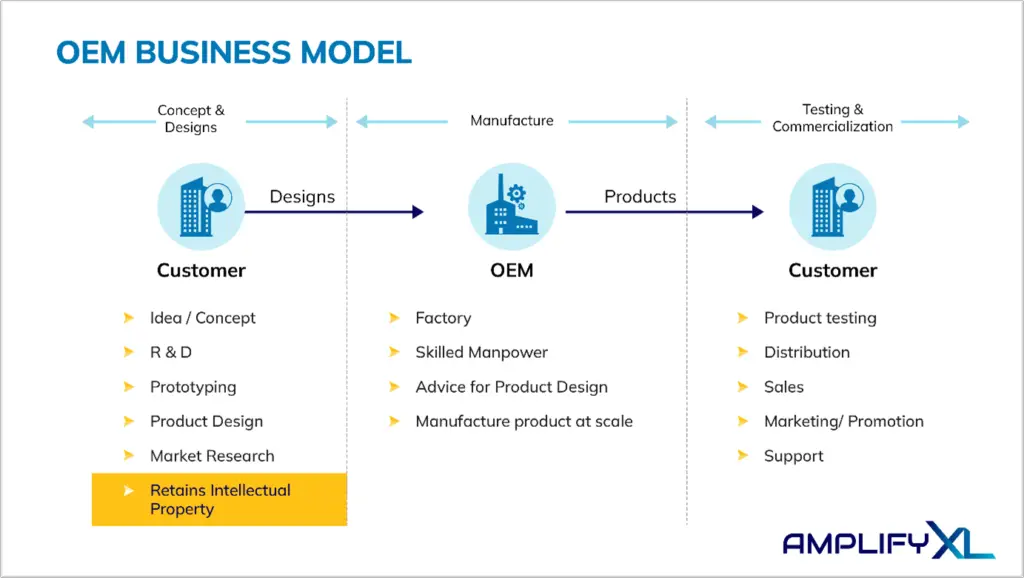

OEMs: A closer look

Broadly speaking an OEM is, first and foremost, a manufacturer. It gets designs from someone else – usually its customer – and it manufactures a product based on these designs.

So, you can think of an OEM as a “manufacturing service”. The OEM will offer you a factory with the necessary equipment and skilled labor. They will manufacture your product and give it back to you.

While the OEM takes care of the manufacturing, everything else is your responsibility – that includes market research, product concept/idea, product design, product testing, marketing, promotion, sales, and support.

Good OEMs will provide advice on your designs so that they can manufacture your product at scale following these designs.

In the OEM model, you, the customer, will retain the ownership of the Intellectual Property and only give up as much as might be needed to allow the OEM to manufacture your product.

ODMs: A closer look

While the OEM focuses only on the manufacture of a product, an ODM is able to conceptualize, design, manufacture, and test a product.

In other words, an ODM is able to take an idea all the way from concept to a finished product.

So, how could an ODM be of use to you?

In one of two ways:

- You have an idea and would like to get it to market as fast as possible without spending a lot on R&D, prototyping, design, etc.

- You see an opportunity for a product that’s already being offered by an ODM, by customizing it and introducing it into a new market.

These two possibilities give rise to two ODM business models: Private Label and White Label.

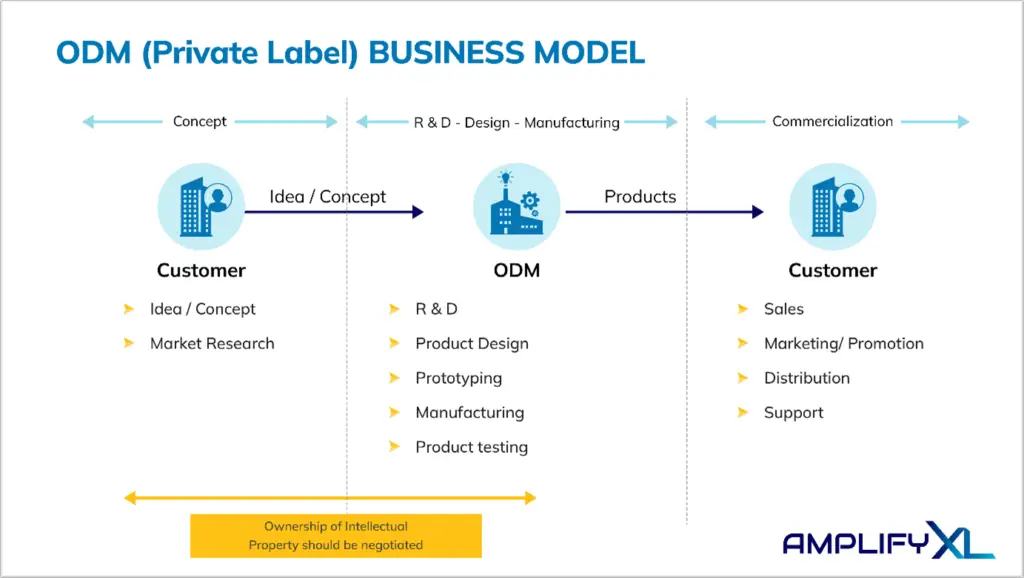

ODM: Private Label

In a Private-label agreement you, the customer, will provide the ODM with your idea or concept and they will provide you with all services needed to manufacture your product at scale.

ODM Private Label services should include:

- R&D

- Product Design and Prototyping

- Manufacturing at scale

- Product testing

The sales, marketing, distribution, and support are still your responsibility. But, depending on what the product is, you could partner with commercial organizations to bring your product to market.

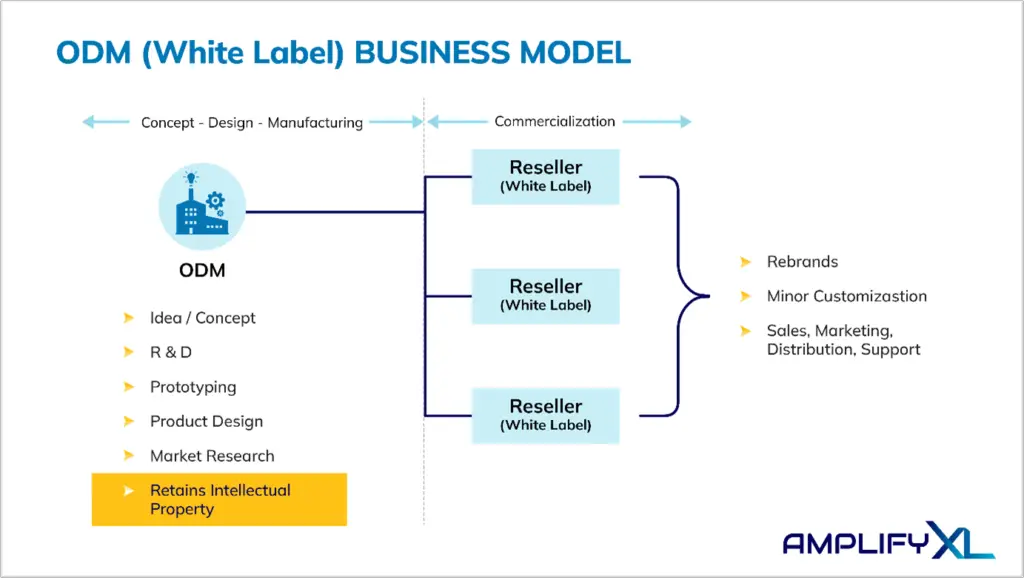

ODM: White Label

In a White-label business model, the product has already been manufactured by the ODM but in a way that it can still be customized (but usually not much).

This business model can work when you’ve identified an opportunity in the market and would simply like to buy a generic product, put your label and your brand on it and sell it.

In this model, the heavy lifting of doing the R&D, product design, product testing, etc. has already been done by the ODM.

So, as long as, the product fits your requirements, this can be a great way to bring it to market with minimal risk and even better – in minimal time.

But most ODMs will require you to purchase in bulk – especially if you select an ODM in China – and so you will carry some inventory risk.

OEM: An example

An electronics company is planning to introduce a new keyboard with a special ergonomic design. The company has a team of electronics engineers, designers, and ergonomics specialists who together have designed the new keyboard.

While the company is capable of designing new products, it does not have the ability to manufacture them.

So, it turns to an OEM.

It supplies the product designs to the OEM which in turn manufactures the keyboards precisely as per the design.

This process involves a lot of back and forth between the designers of the product and the OEM production managers but eventually, the first product rolls off the assembly line.

The electronics company now tests this product and iterates the above process until the products manufactured work as expected.

So, even though partnering with an OEM takes the electronics company a bit longer to get the product to market, they retain full ownership of Intellectual Property while avoiding setting up their own factory.

ODM: An example

Let’s say a sports retailer notices a gap in the local market for special UV Protection sports t-shirts.

They would like to introduce their own branded product to address this gap.

But being retailers, they don’t have the means to research fabrics, design the t-shirts, or build a factory for manufacturing them.

So, they turn to an ODM.

The ODM already has unbranded ready to use UV Protection sports t-shirts for men and women and in various sizes.

The retailer can now:

- select from the different styles and designs available

- choose shapes, sizes and colors

- add their logo

And they have a branded product ready to go.

All intellectual property related to manufacturing the t-shirts remains with the ODM. But the retailer doesn’t mind because they were able to get a product into the market in record time.

OEMs and ODMs: Pros and Cons

Here’s a quick view of the Pros and Cons of OEMs and ODMs:

| Pros | Cons | |

| OEMs | – Bring a product to market without building your own factory – Product can be precisely customized to your needs – You can retain ownership of Intellectual Property | – You need to provide designs to the OEM – Design changes may be needed (to meet manufacturing requirements) – Product testing is your responsibility |

| ODMs | – All you provide is the idea or concept – ODM is responsible for the R&D, design, manufacture, and testing of the product | – Another company now knows how to design your product – Product may not be precisely what you had in mind (with the “white label” model) You will carry inventory risk Intellectual Property could be shared with ODM or owned entirely by ODM |

Pros of OEMs

The biggest benefit of using an OEM is that you can get your product manufactured without the need to set up and manage your own factory, while still retaining the ownership of the Intellectual Property and its exploitation rights.

Further, since you have designed the product yourself, the finished product is more likely to be the way you envisioned it.

Finally, and perhaps most importantly, in the OEM model the ownership of the Intellectual Property remains with you. After all, this was your idea, you did the design (so the patents are yours). All you’re doing is outsourcing the manufacturing to an OEM.

So, try and get OEM input before finalizing the designs.

Cons of OEMs

An obvious con of the OEM model is that doing proper product designs is your responsibility. So, this model assumes that you can do product designs and have the time to do them.

In most cases, you will look for an OEM after you’ve finished your product design. The risk in the OEM model is that the OEM may request a design change to be able to mass-manufacture your product. This could create a lot of back and forth and could hurt your schedule as well as your budget. Worst case, the required design changes are so significant that you’re back at the drawing board.

Pros of ODMs

The biggest benefit of working with an ODM is that all you need to supply is the idea or concept. The ODM will take care of the R&D, product design, manufacturing, and testing of your product.

This can be the fastest way to get an idea to a finished product and into the market.

Cons of ODMs

The downside of the ODM model is that some other company, perhaps at the other end of the world, now knows exactly how to design and implement your idea.

Before choosing the ODM model, make sure you understand this risk.

This also means that a large portion (if not all) of the Intellectual Property in designing and building your product could be owned by the ODM and not you.

Finally, if you choose the “white label” model, your final product will be based on a generic product which the ODM has already produced. And so, the product may not be precisely how you had envisioned it. So make sure that the product you acquire for rebranding still needs the requirements of the market you are trying to serve.

How to choose between an ODM and an OEM

Once your idea, concept, and market research are ready, it’ll be time for you to pick a manufacturing partner.

Choose an ODM if:

- You cannot or do not wish to do product design by yourself.

- You would like to outsource all aspects of the manufacturing process – R&D, production and testing.

- You’ve decided that the best way to get your idea to market is to purchase a generic “white label” product and rebrand it with your brand.

- You do not mind sharing Intellectual Property with the manufacturer or even if the Intellectual Property is already fully owned by the manufacturer.

- You’re comfortable with the product not being precisely what you had in mind as long as it serves the market’s needs.

Choose an OEM if:

- You would like to design your product by yourself or with an in-house team.

- You would like to outsource the manufacture the product.

- Your product needs to be manufactured precisely as per your design specifications.

- You are comfortable being responsible for testing the finished product once you get it back from the manufacturer.

- You would like to retain the ownership of the Intellectual Property behind your idea and designs.

Key Takeaways

- Partnering with an ODM or an OEM is one of the fastest ways to get your idea converted into a finished product and into the market before your competitors without the hassle of setting up, staffing and managing your own factory.

- ODM and OEM are fundamental different business models:

- ODMs offer full-service manufacturing outsourcing including R&D, product design, manufacturing and testing

- OEMs only offers manufacturing outsourcing.

- If you choose as your starting point an existing generic “white label” product made by an ODM, you could hit the ground running even faster. All you would need to do is rebrand the generic product from the ODM.

- Be aware that in both model, all aspects of commercialization of your product – marketing, sales, distribution and support – are going to be your responsibility. In most cases, the responsibility of the ODM or OEM finishes once they deliver you a finished product.

- Finally, take great care in understanding the Intellectual Property risks.

- In the OEM model you can safely retain ownership of the IP. It will, after all, be your idea and your design.

- In the ODM model, however, the design will be made by the ODM. So, who will own the IP? Make sure you find out. Find out how you can protect your idea even if you cannot own the designs.

We hope you found this article useful. We wish you luck bringing your idea to market either with an ODM or OEM.